The NeedleBar

Bobbin Winder Types

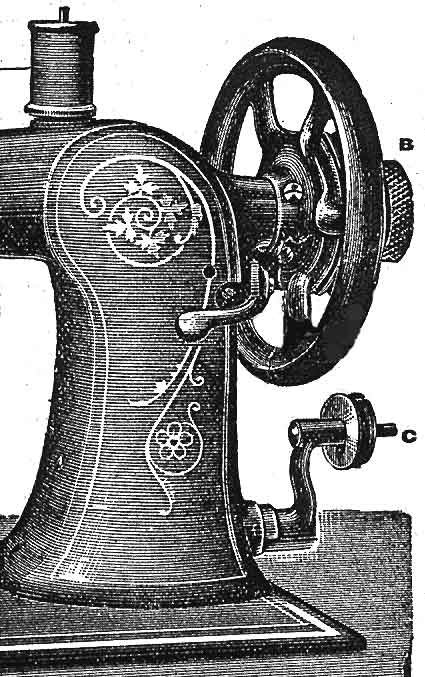

Jones Spool Rotary - 1890's

Courtesy of Claire Sherwell

TO WIND THE SPOOL

First disconnect the Balance Wheel by turning the large milled-edge nut B towards you. This will enable you to wind the Spool without running the machine, and avoids the necessity of having to take the work from under the machine, or breaking the thread.

When you have disconnected the Balance Wheel, then place Spool on Spooler Pin C, pull Winder in contact with the belt, wind end of thread round the Spool two or three times, twisting both ends together with finger and thumb; proceed to wind until the Spool is full. Do not wind the Spool too full.

When the Spool is full, then turn the large milled-edge nut from you to fasten Pulley. Push the Winder from the Belt, and the machine is ready for work again.

© Alan Quinn 2000

This web site may not be reproduced or distributed in part or in whole without the prior written permission of the author