The NeedleBar

Bobbin Winder Types

Gritzner VS (post-1906 first type)

Courtesy of Claire Sherwell

To Wind a Bobbin

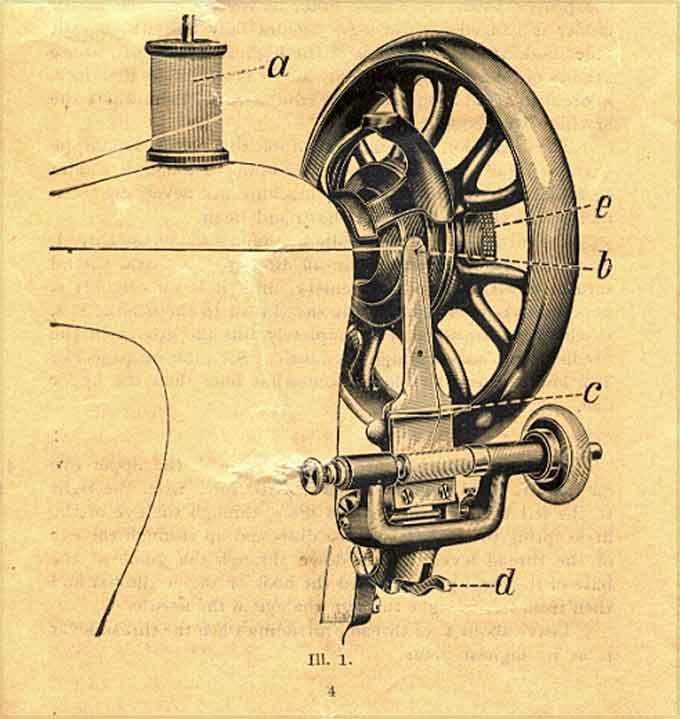

To wind a bobbin disconnect the upper fly wheel and then place the bobbin between the two spindles of the winder so that the flattened end of the bobbin is directed to the right and the pointed one to the left.

Lead the thread from the reel (a) on top of the arm of the machine first through the two tension discs on the thread lever cover plate, then backwards through the hole (b) of the knife blade and again downwards over the bridge (c) and fasten it by squeezing the end between the bobbin and right hand side spindle of the winder. Press the small lever (d) downwards and the rubber ring of the winder will come in touch with the hand wheel, slightly oil the left end of the bobbin and everything is ready for winding.

Care should be taken to always start winding up the

thread at the right hand side of the spool, and not to pass any knots. When

completely filled the winder will automatically cease to work. To avoid constant

interruption of the work it is advisable to wind several bobbins at a time.

© Alan Quinn 2002. All Rights Reserved

This web site may not be reproduced or distributed in part or in whole without the prior written permission of the author