THE NEEDLEBAR

Online Manuals Section

DIRECTIONS AND SUGGESTIONS FOR WORKING

THE

"WARWICK"

FAMILY AND MEDIUM

(LOCK-STITCH)

SEWING MACHINE

Part One

Purchasers should be able to make their machines quite useful

in a few days' time; if they do not, it is for want of proper instruction for

which they will please apply to the party who furnished the Machine.

SOLE MAKERS:

HENRY WALLWORK & Co.,

CITY SEWING MACHINE WORKS

HILTON STREET

Show Rooms and Offices - China Lane, PICCADILLY,

and

UNION BRIDGE FOUNDRY, CHARTER STREET, MANCHESTER.

_________________________

| Telephone - No. 567 |

Telegraphic Address --- "Foundry,

Manchester"

|

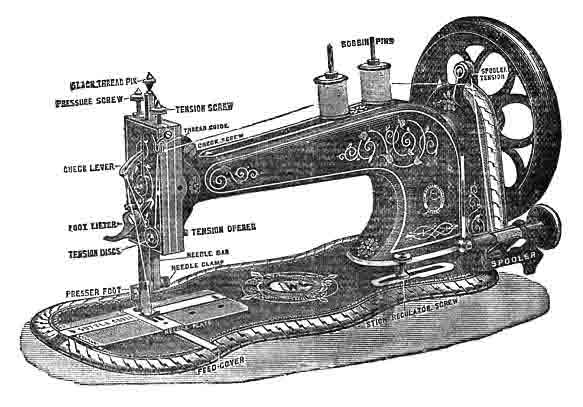

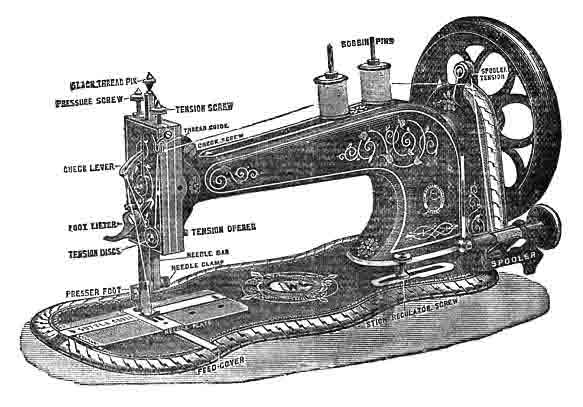

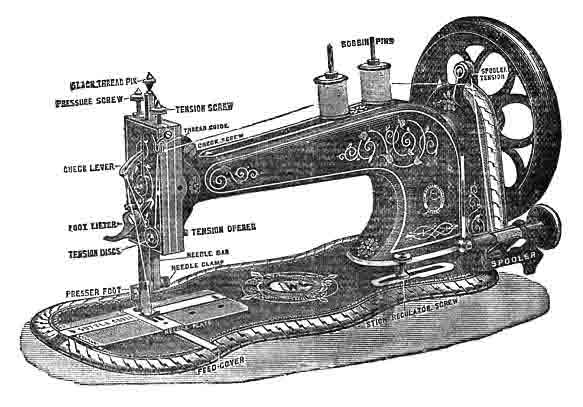

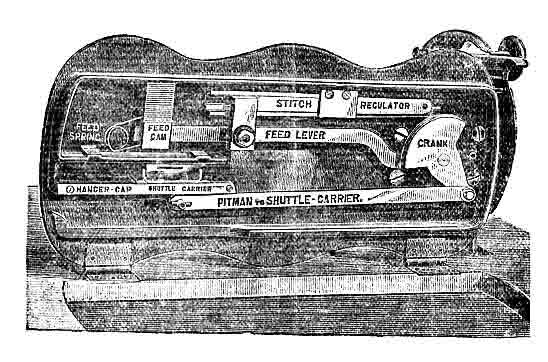

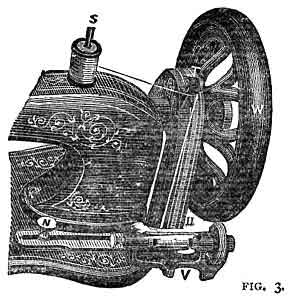

Refer to these cuts for the Technical

Names of the parts of the Machine.

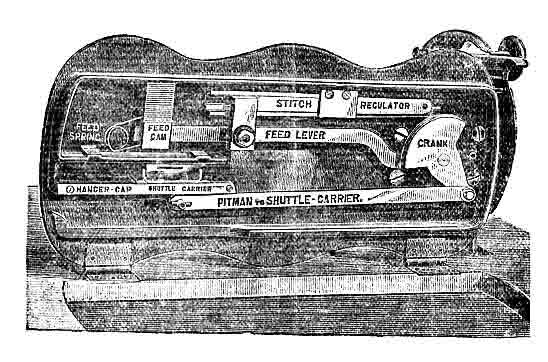

This Cut represents the Machine

turned on its hinges, showing the parts on the underside.

THE AUTOMATIC

SPOOL OR REEL WINDER

<--------->

The most Mechanical Spool Winder

in the World.

To Wind the Bobbin or Spool for

the Shuttle

|

The Screw at the end of Shaft that

secures the Balance Wheel is a left-

handed screw, and to take off the

Balance Wheel

|

|

You must turn the Screw from

left to right, just the opposite to

the usual direction of Screws.

|

Fix the reel in the winder, press the winder so that

the India-rubber pulley comes into contact with the balance wheel, place the

bobbin upon the pin (S), pass the cotton through the hole at (T)

down to the winder, underneath the straight wire (U) from back to front,

then from right to left behind the cotton which descends to put a twist in

the cotton, and pas it through the hole at the left end of the reel. Turn

the wheel towards you with the right hand, holding the end of the cotton with

the left, until it is held by the reel, then break off the end, turn the wheel

again until two rows are wound upon the reel, raise the pressure-plate so

that it comes into contact with the reel, and proceed to treadle until the

reel is full. It is important that the straight wire be kept smooth and free

from rust.

TO COMMENCE SEWING

Open the left-hand shuttle cover, place

the shuttle in its carrier, leaving out about three inches of thread, and close

the slide plate within about an eighth of an inch; draw about three inches of

thread downward from the check-lever and through the eye of the needle, holding

the end with the left hand, allowing to to be slack from the hand to the

needle, while you turn the balance wheel towards you, until the needle moves

down and up again to its highest point; pull the needle-thread gently, and

the shuttle-thread will appear with it, then close the shuttle cover. Leave

the threads to the left across the feed points under the foot, place the fabric

under the needle, lower the lifter, and commence sewing. Having made a few stitches,

stop and examine them. Our Machines make the lock-stitch thus -  It

is a stitch that will neither rip of ravel. The tension should be thoroughly

understood; if the thread is straight or in loops on the under surface of the

fabric, thus -

It

is a stitch that will neither rip of ravel. The tension should be thoroughly

understood; if the thread is straight or in loops on the under surface of the

fabric, thus -  turn the tension screw from right to left to loosen the needle thread, or tighten

the shuttle thread as instructed.

turn the tension screw from right to left to loosen the needle thread, or tighten

the shuttle thread as instructed.

TO ADJUST THE NEEDLE

Allow the needle-bar to rest at its

highest point, and loosen the needle clamp nut. Take the needle between the

thumb and forefinger of the left hand, having its long groove towards you, and

put the point down through the hole in the needleplate; turn the wheel gently

towards you, while you guide the needle under the needle-clamp; then tighten

the clamp-nut; with the left hand insert the point of a fine needle into the

eye, resting it on the needle-plate; loosen the clamp-nut, and pressing the

fine needle into the eye in a direct line from you, turn the wheel gently towards

you, until the gauge mark (a line graven in the needle-bar, near the top) is

level with the top of the arm; then tighten the clamp-nut.

TO ALTER THE LENGTH OF STITCH

The stitch-regulator screw is adjustable

in a slot, immediately to the left of the winder. To lengthen the stitch,

loosen the screw and move it to the right; to shorten the stitch, move

it to the left. After adjusting the length of stitch, tighten the screw.Note.-

When the screw is at the end of the slot, and the stitch not as short as desired,

change the screw into the hole at the end of the regulator slide, then move

it still further to the left.

TO REMOVE THE WORK

Stop the Machine with the

needle-bar at its highest point, raise the foot lifter, draw the fabric from

the left side of the presser-foot upwards about three inches; then cut the

threads, leaving the ends long enough to re-commence sewing. Seams requiring

to be extra strong at the ends should be secured by taking a few stitches in

the opposite direction before removing it, the same as in hand sewing.

TO OIL THE MACHINE

If the machine is only used occasionally,

it requires but little oil and in the following places: The sides of the needle-bar,

the four holes on the top of the arm, the two holes on the side of the arm,

the shuttle carrier slide, both ends of the shuttle-carrier pitman underneath

the machine, and all other joints and slides having motion. After oiling, put

the machine in rapid motion for a few seconds, without sewing, and wipe off

all the superfluous oil.Note.- If the machine is in constant use, it ought to

be well oiled twice a day in all the places enumerated above, and also on the

following places: Each end of the treadle where it rests upon the centres, both

ends of the wooden pitman, the hinge of the check-lever, the stitch regulator

slide, the spooler-spindle, and the top of the lifter, inside the slot. Also

the stand wheel, and all other joints having motion.

![]()