THE NEEDLEBAR

Online Manuals Section

INSTRUCTIONS FOR USING THE

NEW WILLIAMS SEWING MACHINES

Part Five

HINTS TO THE USERS OF THE "NEW WILLIAMS"

----- : : : -----

|

No. 1. --- Do not expect to get along entirely without trouble. Difficulties will arise of a more or less serious nature. Poor thread, defective needles, bad oil, etc., lead to these; and, remember; that you yourselves are liable to make mistakes in threading and handling the Machine. Should it fail to give satisfactory results, in any particular point, refer at once to the directions for that point, and they will always help you out.

|

|

|

No. 2. --- If upper thread breaks, the needle is not set correctly; or the Machine is not properly threaded; or the upper tension is too tight; or the needle is too small for the thread; or the eye of the needle is sharp or rough; or the point of the needle is bent or broken; or the Machine has turned toward you instead of from you, or the thread has slipped from under thread guide behind needle bar. See page 4.

|

|

|

No. 3. --- If the under thread breaks, the bobbin has been filled too full; or the thread has been too unevenly wound; or the thread has not been properly drawn into the shuttle; or tension of the shuttle is too tight; or the tension spring may have got bent.

|

|

|

No. 4. --- Needles are broken (nine times out of ten) by pulling the goods when sewing. Let the Machine do its own feeding. If the stitch is not long enough, lengthen at the proper place. Too fine a needle for the size of the thread used will also be apt to break the needles.

|

|

|

No. 5. --- If the upper thread loops, the tension is too loose; or the take up - see page 4 - is not threaded; or the thread is tangled somewhere. Too loose a tension on the shuttle thread, or the thread not properly drawn into the shuttle, will case the under thread to loop.

|

|

|

No. 6. --- If "skip stitches" are being made, the needle is not set correctly; or it has got bent; or it is too fine for the thread; or better decide that it is a bad needle, and set another.

|

|

|

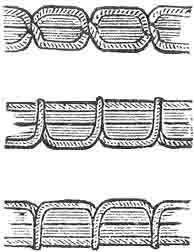

No. 7. --- PERFECT STITCHING. - This will result when the upper and under threads evenly balance each other (tight enough to lay the threads smoothly yet not so tight as to pucker the cloth), the thread being locked in the centre of the goods, thus,

|

|

| If the thread is straight on top, thus, the upper tension is too tight or the under tension is too loose. | |

| If the thread is straight underneath, thus, | |

|

the shuttle tension is too tight, or the upper tension is too loose. If both upper and under threads appear loose (not smoothly drawn into the cloth), then both tensions require tightening. NOTE. --- A short stitch will bear a tighter tension than a long one; so it is well when you lengthen the stitch to loosen the upper tension a little, especially on fine goods.

|

|

|

No. 8. --- The main cause of Machine running hard is gummed oil. Oil Machine with kerosene, run until perfectly free, then wipe clean and oil afresh with good oil. Too tight a belt will also cause the Machine to run heavy; whilst too loose a belt will slip, and cause the Machine to run irregular.

|

|

|

No. 9. --- BAD THREAD. --- Whilst nearly all the different makes of thread are good, and give satisfactory results, some are so bad as to be unfit for machine use, and some even of the best, from being too exposed to dampness, will become spotted with mildew. Such thread if put on the Machine, will give trouble in breaking, as a matter of course. See that your thread is of good quality and free from "knots". Never wind a "knot" on the bobbin. The PRESSER FOOT should never be let down on the FEED, unless when you are sewing and have cloth under it. Do not run the Machine with either of the shuttle slides open. Do not use a dull or bent needle, or draw the work faster than the feed will naturally carry it. Needles are frequently broken by failing to observe the latter caution. |

|

THE WILLIAMS MFG. CO. LTD.

MANUFACTURERS OF

Sewing Machines

MONTREAL, CANADA

Plattsburgh, New York, U. S. A.

Part One | Part Two | Part Three | Part Four