is

perfectly set.

is

perfectly set.The Needle in this Machine is self-setting, the operator simply

pushes the Needle up the hole in the Needle Bar as far

as it will go, with the long groove to the

left hand; secure the Needle firmly with the Needle

Screw and the Needle  is

perfectly set.

is

perfectly set.

Be sure the Needle point is sharp not blunt. This is very important, particularly so when sewing fine goods.

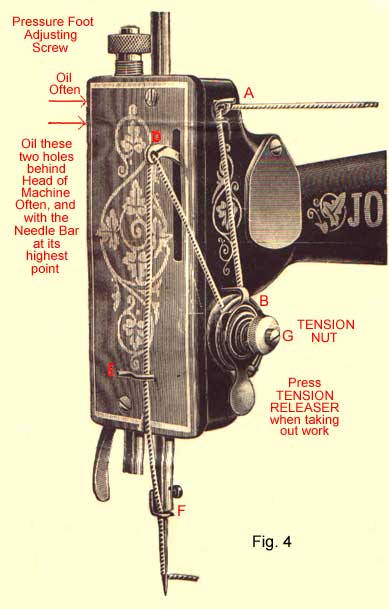

Place the spool of thread on the Spool Pin, pass the thread through the Eye marked A, then between the Tension Discs B, and into the slot in the Take-up Lever D, behind the Guides E and F, and through the Needle Eye, the thread running through the Needle Eye from left to right.

The Needle or Top Thread Tension is adjusted by means of the Milled-head Tension Nut G (see illustration).

By turning the Nut G to the right hand, the tension is tightened or increased.

By turning the Nut G to the left hand, the tension is slackened or decreased.

Always be sure that there is some tension on the top thread, or it may tangle round the Shuttle.

First disconnect the Balance wheel by turning the large Milled Head Nut at the end of the shaft (Fig 1) towards you, this will enable you to wind the Bobbin without running the machine, and avoids the necessity of having to take the work from under the machines, or break the thread.

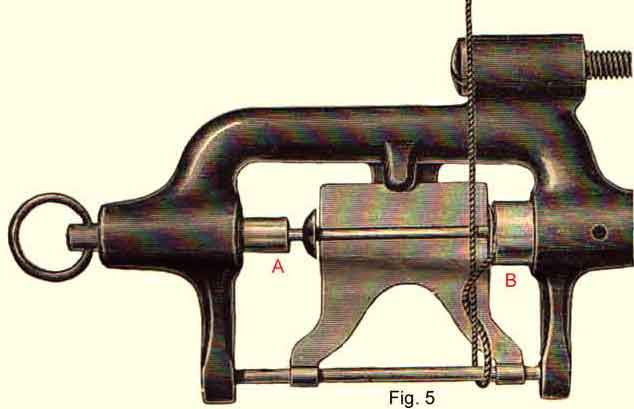

Place the end of the Bobbin in the Winder Centre A, forcing the Winder-Centre to the left far enough to allow the other end of the Bobbin to go into the Cup-end of spindle B. You will notice the Cup-end of Spindle is hollowed out, so that you may easily see the Pin that goes into the hole in the end of the Bobbin.

Be sure that the hole in the end of the Bobbin is right opposite the Pin in the Cup-end of the Spindle B. Then push the Bobbin Winder up aginst the the Balance Wheel, which will drive the Winder whilst winding. Place the spool of thread on the Spool Pin and pass the thread through the Eye A, (see Fig 4), then through the Eye just above the Bobbin Winder and thence to the Winder.

This Winder is self-acting, and winds the thread on to the Bobbin as evenly and as regularly as an ordinary spool of thread. It is the most simple and effective Bobbin Winder ever invented.

Never attempt to turn the Machine over for oiling with the Back Shuttle Cover Slide part way out, or you will damage the Machine.

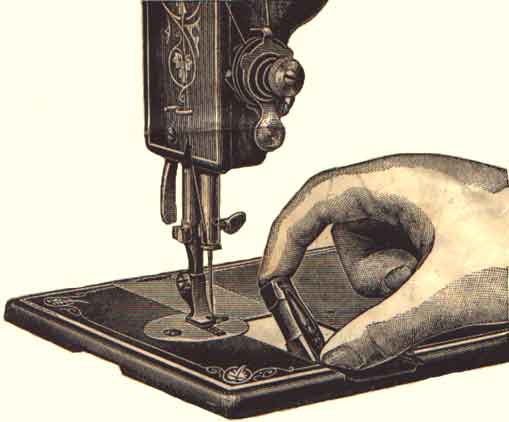

Withdraw the Front Shuttle Cover Slide. Turn the Balance Wheel until the Shuttle Carrier is as near to the front of the Machine as it will come.

Press

down the Point of the Shuttle with the Thumb

and it will lift the back end of the Shuttle clean out of the Shuttle Carrier

(as illustrated)

Press

down the Point of the Shuttle with the Thumb

and it will lift the back end of the Shuttle clean out of the Shuttle Carrier

(as illustrated)

NEVER attempt to lift the Shuttle out of the Carrier BY THE SPRING, or you may damage the Shuttle Tension.

-

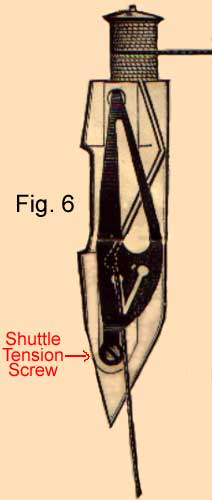

Take the Shuttle in the left hand, between the thumb and the two first fingers, with the Shuttle point towards you. Fig 6 shows you how to put the Bobbin into the Shuttle. Be sure that the thread runs off the top side of the Bobbin (as illustrated). This is very important.

Press the end of the Bobbin down to the bottom of the Shuttle and hold it there with the fore-finger, and with the right hand pull the thread down the slot in the shuttle as far as it will go (see Fig 6).

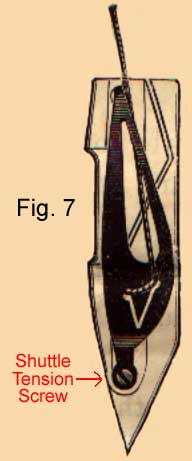

Now pull the thread back again towards the back end of Shuttle (as shown in Fig 7), and the Shuttle is threaded without having to pass the thread through a single hole -- in fact, this Shuttle is really, and absolutely, SELF-THREADING.

-

When the Front Shuttle Cover is withdrawn, be sure you Oil the Cotton in the cup that lubricates the Shuttle and the Shuttle-race. This is important.

TO

REGULATE THE SHUTTLE TENSION

TO

REGULATE THE SHUTTLE TENSIONAlways use the special small Screw Driver, so as not to damage the Shuttle Tension Screw.

By turning this Screw to the right, you increase or tighten the Shuttle Tension.By turning this Screw to the left, you decrease or slacken the Shuttle Tension.

The Shuttle Tension should never be as tight as the Needle or Top Tension.

Withdraw the Front Slide that covers the Shuttle. Turn the Balance Wheel until the Shuttle Carrier is in the position for you to place the Shuttle into the Carrier. The Balance Wheel should always turn towards you.

Hold the end of the Needle or Top Thread between the thumb and finger of your left hand, then turn the Balance Wheel towards you, until the needle moves down and up again to its highest point, and you will find the Needle or Top Thread will catch and pull the Shuttle Thread up through the Needle-plate hole.

Now close the Front Slide, place both ends of the threads, also the material to be sewn, under the Presser-Foot; then lower the Presser-Foot, turning the Balance Wheel towards you, and commence sewing.

In sewing soft, thin fabrics, the Tension should be light and easy; on thick and heavy goods it should be tight.

Insewing seams where strangth is required, the Tension should be alike on both threads, in order that the lock may be in the centre of the goods, thus -----

If the lower thread lies straight on the underside of the goods, thus -----

the Shuttle Tension is too tight, or the Needle or Top Tension too loose.

If the upper thread lies straight, the Needle or Top Tension is too tight, or the Shuttle Tension too loose.

In stitching goods which are too thin to conceal the lock of the threads in the centre, the lock may be thrown in the direction of what is to be the "wrong " side of the finished work so as to present a better appearance on the "right" side.

Always have the Needle Bar at its highest point. With the forefinger of the right hand, lift the Presser-Bar, and at the same time press with the thumb upon the Tension Releaser (Fig 4); this liberates or slackens the thread in the Tension, and you can easily draw the work from under the Presser-Foot without any fear of bending the Needle or breaking the threads. Then cut the threads, leaving the ends long enough to recommence sewing.

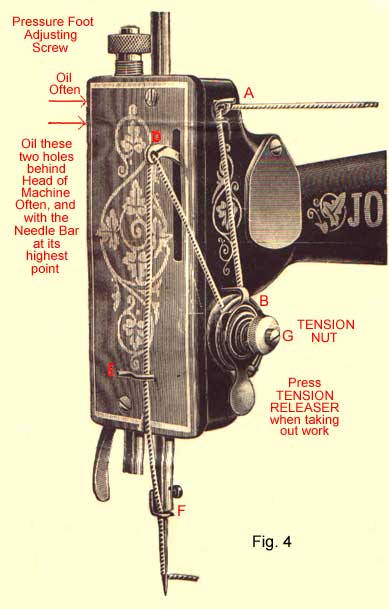

(See Stitch Handle close to Balance Wheel, Fig 5)

By lifting this Handle upwards, you make the stitch longer.

By pulling the Handle down, you make the stitch shorter.

CAUTION -- If you pull this Handle down as far as it will go, the machine will not feed or carry the work forward at all.

(So as to put more pressure on the material)

Turn the Milled-Head Presser-Foot Adjusting Screw (Fig 4) at the top of the Presser-Bar to the right, to increase the pressure; or to the left, to decrease the pressure. For ordinary domestic sewing it is very seldom necessary to alter the pressure on Presser-Foot, but on thin soft fabrics the pressure should be light, on thick materials it should be heavier.

******************************************

Be sure and take particular notice that the Balance Wheel must turn towards you.

Sharp pointed Needles. It is of the utmost importance that the Needle has a good sharp point.

If the Needle thread breaks when the Needle is adjusted properly it is caused by the Top Tension being too tight, or the eye of the Needle being too small for the thread, or the eye of the Needle being rough or sharp; or the Shuttle, or Shuttle Carrier, being rough or damaged.

If the Shuttle Thread breaks, slacken the Shuttle Tension, by unscrewing the small Shuttle Tension Screw at the point of the Shuttle.

The Needle must be pushed up the hole in the Needle Bar as far as ever it will go, and then it is sure to be in the right place.

Missed Stitches are caused by the Needle being bent away from the Shuttle, or by a crooked Needle, or if the Needle Eye is too large for the thread.

If the thread is improperly or too tightly twisted, it may throw the loop towards one side, instead of throwing the loop square into the Shuttle-race. In that case the Needle should be slightly turned in an opposite direction to counteract this tendency to throw the loop away from its proper position.

Always use the best soft finished cotton, because it makes better work and is the cheapest in the end.