NOTE: This very jingoistic and somewhat naive article was written sometime around 1918. It is of historical importance however.

Courtesy of Jenny Sims & Jan Cnossen

TURNING VICKERS GUNS

INTO

SEWING MACHINES

HOW ONE OF THE LEADING ARMAMENT MANUFACTURERS OF BRITAIN IS APPLYING A FAMILIAR BIBLICAL PRECEPT

BY

FREDERICK A. TALBOT

AUTHOR OF "INVENTIONS AND DISCOVERIES" "THE RAILWAY CONQUEST OF THE WORLD" "THE OIL CONQUEST OF THE WORLD", ETC., ETC.

Was it worth it? When the German nation, in a sober moment, sits down to ponder over its national profit and loss account, and surveys the ruins of its former commercial and industrial prosperity, thsi reflection will defy submersion. Its persistent rise to the surface of thought will bring home to the contemplative Teuton, perhaps for the first time the depth of the pit into which his country has been flung as the outcome of the bout of world-power intoxication.

Germany's disaster has proved Britain's salvation. Today, likewise in a moment of calm consideration, we recognise the extent of our past folly in having patronised so freely the shop and manufacturer on the other side of the North Sea. We appreciate somewhat poignantly how one British industry after another has toppled and fallen before the insidious, invariably unscrupulous, aggression of the apparently complaisant Teuton carpet-bagger. British brains were fertile in evolving new ideas and opening up new fields for commercial activity and wealth, but almost without exception, it was the German who annexed the one to exploit the other, to our discomfiture.

Take the sewing machine as a case in point. I purposely slect the inseparable companion of the housewife and the clothing manuafcturer because it constitutes the theme of this story. It was a British brain which first conceived it to be far easier to sew by mechanical agency than by hand. But Saint's sewing amchine was as far in advance of its day in 1790 as was Brunel's Great Eastern in 1859. Another fifty years were destined to slip by before the world deemed it necessary to supersede tedious and laborious hand-needlework by the machine, and it was a combination of British and American brains which wrought the revolution. A new industry was founded in Britain to flourish amazingly for a few years.

Vogue of the Hire-Purchase System

But with the lapse of the master patent the outlook underwent an unexpected and dramatic change. A new rival, also American, appeared upon the scene to conduct commercial operations along entirely new lines. Heretofore the sewing machine had been sold upon the accepted cash basis, and the figure was relatively high. It appealed only to the somewhat exclusive public, for the most part finding a sale among the trades specialising in the manufacture of wearing apparel. It was virtually unkown in the home, mainly for the reason that it was beyond the reach of those to whom it would have meant so much.

The new American competitor set out to bring the sewing machine within reach of those classes of the community which the British industry had either overlooked or neglected, and more particularly the poor seamstress to whom it represented a means of improving a precarious existence. Needless to say, in the circles it met with a ready welcome, primarily because its acquisition by those slender of purse was facilitated by the introduction of the instalment or hire-purchase system. The weekly payment was purposely set attractively low to enable the cost of the machine to be defrayed out of the increased income which its employment enabled to be won.

This method of conducting the sewing machine business attained and enormous vogue, and the British trade was hit hard. Before long the bulk of the manufacturing side of the industry passed to the United States, where, by the adoption of elaborate standardisation methods, coupled with big-scale production, the cost of manufacturing the machine was forced down to a very low level to leave a very wide margin between the prime cost and the retail figure.

The German Invasion

Meanwhile the Germans had grown active. They had been taking stock of the whole situation as it prevailed in Great Britain and her colonies, and with characteristic ingenuity had resolved the success achieved byu the American company into cold statistics. The market was growing rapidly and presented illimitable possibilities. So the calculating Teuton decided to enter the lists.

The attack was prepared very carefully, excellently camouflaged, and driven home persistently, though unostentatiously, so as to arouse no suspicion of intent. There was no flourish of trumpets nor flamboyant display of advertising. That was not the German way to get a foot in. Peaceful penetration was the guiding principle, and the lines of least resistance were followed.

Yet the observant mind might have learned that the German aggressor was rapidly gaining ground. Additional sewing machine manufacturies commenced to spring up in the land beyond the Rhine. But the reason for their creation was cleverly obscured. Ostensibly they were being brought into being to feed the increasing home market, which certainly was becoming a force to be considered, but in truth, they were being provided to satisfy the rapidly-growing potentialities of the British and Colonial market, which was far more fertile.

A Romance of Energy and Imagination

Thirty-three years ago an energetic and imaginative young man in the City of London became attracted to the sewing machine market. Reconnoitring the situation he discovered that, despite the competition which was rife, an excellent, attractive and extensive field was still awaiting exploitation. A golden opportunity was open to the British industry to re-assert itself, and in no uncertain manner, if it were but boldly seized.

Chance threw this young man into the arms of a German firm which was keenly bent upon winning recognition in Britain. It was in search of a live man on the spot to enable it to achieve its end.

In the German manufacturer the Englishman found a kindred spirit. The issue was discussed in all its bearings, and when at last the anxious Teuton asked if the Britisher would handle the German machine, a prompt acquiescence was extended on the firm understanding that the manufacturer would provide and article strictly in accordance with the requirements of the market.

The young Englishman settled down to his work, and, as he had confidently expressed to the unsympathetic British members of the industry, the market was waiting for what he had to offer. His machine coincided with popular requirements, was so soundly constructed as to win the complete confidence of both the buyer and seller, and was sold at an attractive cash figure -- one far below the prevailing price. He created a totally new outlet for sewing machines, opening up a field which hitherto had escaped attention, but which, as results proved, is one of the richest in the whole country. The Colonial market was equally responsive; it was offered what it wanted.

The German Triumph

It is possible to drive home the lesson which this combination of British selling brains and German producing enterprise teaches. The effect of British selling energy is reflected by the prosperity of the Teuton manufacturers. It directly stimulated the creation of a huge industry in the land across the Rhine.

The growth was so striking that by 1914 Germany could point to twenty big factories turning out sewing machines, in addition to ten equally imposing concerns specialising in nothing but spare parts. In the United States there were only seven companies devoted to this product. Germany had become the foremost sewing machine producing country of the world, the value of the exports -- of complete machines and parts -- exceeding £2,257,000 for the year 1913.

Today we are wiser. The declaration of war hurled the German sewing machine industry to utter ruin. Thirty-six years studious, unremitting cultivation of the British market was undone in one fell swoop. At this moment the British attitude towards any product of German origin is so hostile as to preclude all possibility of the error in the Teuton body politic and military being rectified for many years to come, if ever.

Other Times, Other Methods

Hostilities caught Mr. Pierssene, the enterprising Englishman in question, at a heavy disadvantage. On the one hand he was cut off from his source of supply, on the other hand there was a huge market hungering for the sewing machine he had been able to offer. Now was the grand opportunity for the British industry to step in and to recover the whole of the ground it had lost. Its most formidable competitor had been swept aside so that the issue for supremacy became narrowed down very considerably.

But as times had changed, so had the methods. The British sewing machine trade never could aspire to achieve a position comparable with that attained by Germany unless production was conducted along spectacular lines. The rapid deelopment of the industry in Germany and the United States, which had provoked acute competition, had brought about extreme ingenuity in the reduction of prime cost of production.

Intimate acquaintance with the situation in all its phases convinced Mr. Pierssene that, so far as Britain is concerned, manufacture could only be conducted with any prospect of commercial success, comparative with that recorded by the Germans, by a firm possessed of enormous resources in every essential direction -- financial, material, mechanical and labour. The outlook for the British-built machine was never so promising; a wave of patriotism was sweeping the Empire.

From Battleships to Sewing Machines

There was only one firm in particular which, if it could only be perusaded to consider the new range of industry as a serious proposal, would be magnificently qualified to attack the problem. It was even more completely armed for the conquest than the German factories ever had been, inasmuch as it had control of the necessary materials from Mother Earth to the last stage of production and dispatch. Moreover there were the firm's name and worldwide reputation, which alone would prove of inestimable value wherewith to assail the markets of the whole globe.

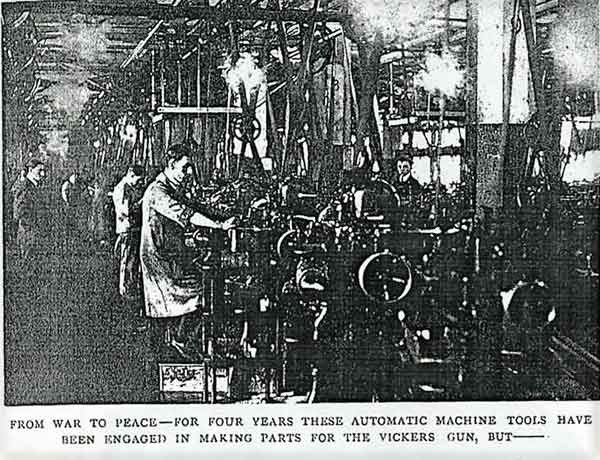

The firm in question was Vickers Limited. From ponderous super-Dreadnoughts and mighty 15-inch guns to puny sewing machines may seem a very far cry. But manufacture is purely a matter of degree. The production of a big or little gun calls for the handling of integral parts just as small as any incidental to the housewife's mechanical friend and helpmeet, while the latter demands as fine work and strict adherence to the extreme minute fraction of an inch as the machinery of a battleship or the mechanism of its armament.

The proposal was submitted to the firm and was explained in detail. The opinion was confidently expressed that a machine of Vickers construction, coinciding with the desires of the purchasing public in questions of design and price, would succeed even more triumphantly in the future than had the German rival in the past. The firm listened and was favourably impressed, the circumstance that the sewing machine offered an attractive field for manufacturing activity and the utilisation of one or more of the many war factories which had been created proving a decisive factor.

Within a few days the project had been closely investigated, the possibilities of the potential market probed, and a decision reached. The builders of battleships and big guns would assume the production of a sewing machine, would bring all their many and varied resources to bear upon the enterprise to carry it to success, and would undertake manufacture upon a scale befitting the magnitude and capabilities of Vickers Limited -- exceeding the limits previously recorded by the specially built and equipped German factories. Mr. Pierssene agreed to accept responsibility for the selling end and to pursue the lines he had followed so successfully with the Teuton article.

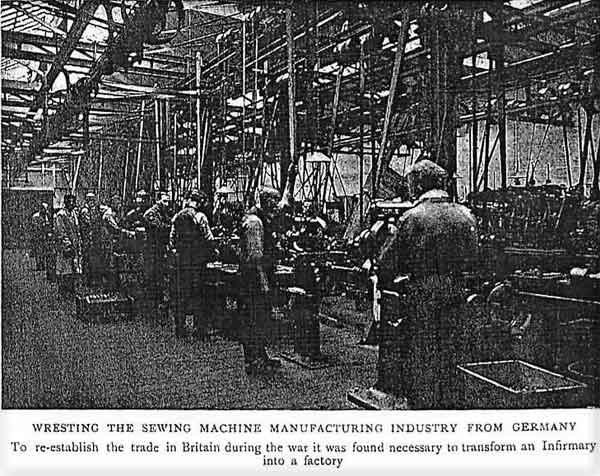

Re-establishing a Lost Industry

The famous armament firm is nothing if not ready to act at once. Sewing machines were in urgent request in all directions, not only by the civil members of the public throughout the world, owing to the German sources of supply having been summarily cut off, but for the equipment of the thousand and one factories which were being brought into being in these islands to make the innumerable textile articles demanded by the services, from uniforms to tenst, machine-gun belts to aeroplane wings, airships to mattresses.

The world was being ransacked for machines, and to ease the national situation the armament manufacturing organisation decided to extend practical assistance. The drawing office was set to work to elaborate the designs, Mr. Pierssene being requested to bring his accumulated experience concerning the subject to bear upon the evolution of what might be described as the last word in this realm of activity. Meanwhile architects were urged to complete designs for a large factory with all speed, while other members of the huge organisation were detailed to secure machine tools, jigs, patterns and material, as well as labour, so that the moment the new factory was completed and equipped the production of the new article might be launched and set in full swing without delay.

But the manufacturers had omitted to take the enemy, or rather the British military authorities, into consideration when maturing their ideas. The new factory had scarcely received its roof when along came the War Office with a request for more and more machine-guns. Why? The new building was splendidly adapted to increase the output of the quick-firing arm. Forthwith it was diverted from its avowed mission of peace to one of war.

Determined not to be denied in its intentions, the company started work on another building. While this was going up the demand for machine-guns took another startling turn, and one which threatened to leave supply hopelessly eclipsed. The sudden impressment of this second building to the quick-firing weapon brought home to the firm tha fact that the war would have to be finished before the sewing machine could be taken seriously in hand. So, with extreme regret, the undertaking was shelved for the time being, the salesman being requested to explain the situation to his anxiously waiting clients and to ask their forebearance.

Putting Interned Alien Mechanics to Work

But as the war pursued its fluctuating course the Vickers Company chafed at the necessity to postpone the sewing machine for an indefinite period. A magnificent opportunity was slipping through its fingers; it was even being denied the chance to turn a spell of enforced inactivity to the fulfilment of that phase of experimental work incidental to every new range of manufacture.

It was also being deprived of the ability to carry out what might be termed the educational side of the issue, to introduce the machine to the public, and to familiarise the latter with its outstanding virtues and capabilities. This handicap was particularly galling because it so happened that at tha moment competition had reached its very lowest ebb, the importation of American machine to British civilian account having been prohibited, the home market thus being brought to a complete standstill.

The prevailing state of affairs prompted a further consideration of the whole situation. The firm had not a building, a tool or even a mechanic which it could spare to conduct the indispensible preliminaries -- all had been impressed to fulfil work of vital national importance. Suddenly its attention was diverted to the army of interned German civilians, in the ranks of which were some skilled machanics. They were twiddling their thumbs and kicking their heels in idleness behind barbed wire and living at the country's expense. Why not give them the opportunity to perform useful work?

There was no logical reason why they should not be enabled to earn their own living if they felt so inclined. The chances were that the majority of those who were skilled would gladly seize the opportunity to while away the tedium of their confinement in remunerative occupation. It would at least offer an effective palliative against fretting. We were not disposed to emulate the example of the enemy who did not hesitate to compel his prisoners to assist in the fulfilment of direct and indirect military duties.

The authorities approached the firm and a practical scheme was submitted for consideration. The Government expressed its readiness to secure a suitable building coinciding with all the essential conditions of internment, and to offer steady, regular employment to all those who were disposed to secure the opportunity to occupy their time and mind to individual financial advantage. No sweating or other deprecatory tactics would be practised. The men would be paid the standard rate of wages as settled by the union in connection with the employment of British employess, and if, after a time, a man should tire of his task, he shold be permitted to return to his camp. No irksome conditions were to be attached to the employment regulations beyond those demanded by the authorities concerning adequate isolation from the outside world.

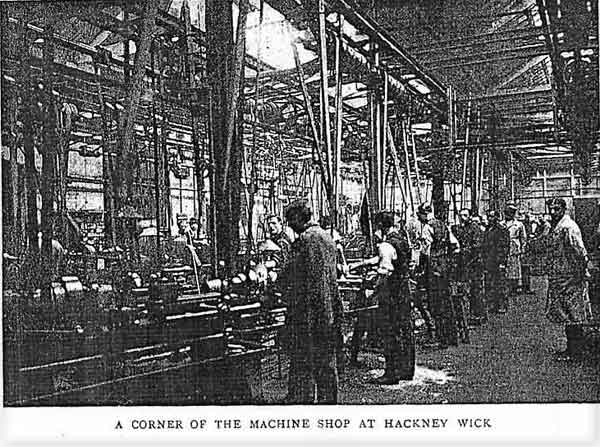

At Hackney Wick a building which had been provided originally to house the aged and infirm poorer members of the community, but which was no longer required for this purpose, an infirmary to wit, and which was excellently adapted to the scheme, was taken over. The essential alterations to adapt the institution to the new conditions were completed, tools were installed, and those aliens who were perfectly willing to continue the practice of their craft during their period of internment were transferred to this centre.

Educating the Public

In such a somewhat curious manner as this was born the lates range of the varied activities of the Vickers Company. Probably it is without a parallel in the whole range of industrial effort. From this extemporised hive of activity, where the men have been permitted to work practically as they felt disposed, free from all the pressure imposed by severe competitive conditions, and where they have been paid the same wages as they could have commanded had they been left free to pursue their occupations outside, has issued a steady stream of sewing machines.

True the contribution has not been heavy, but it has achieved the object of those fathering the undertaking. The machines which have been forthcoming have been strategically distributed throughout the wide market to which appeal is to be made eventually upon a large scale; have familiarised the patient buyers with the article and its salient characteristics; have introduced the name of Vickers in its association with this industry to the trade. Moreover, these manufacturing facilities, though limited, have enabled the company to overcome the many little difficulties as they became manifest, and have facilitated the embodiment of certain improvements in detail both as regards design and production. In a way the Hackney Wick establishment may be likened to a well-equipped and extensive laboratory -- one which not only is devoted to experiment, but which is capable of fulfilling a certain measure of actual production as well.

This successful utilisation of interned alien labour supervised by skilled English mechanics has not met with unqualified favour on all sides. Effort has been made to turn to capital account the circumstance that while the machine is undoubtedly British in conception and is made from British materials, yet it is being made by foreign labour, and therefore to a certain degree is an alien product. Such a contention is peurile and likely to exercise and unwelcome boomerang effect.

In the past, to our national discomfiture, there has been too pronounced a willing tendency to make avail of foreign labour in our factories on the scarcely tenable, and certainly frail, representation that the foreign workman is more industrious than his British contemporary. As events have proved, firms utilising such labout have been selected especially by enemy rivals as fruitful ground for the planting of expert workmen in the confident knowledge that they would acquire all the requisite information to permit the rival in Germany to compete on a more even footing, the workmen having been the vehicle through which valuable and often secret details have been transferred from this country to that astride the Rhine. In this particular instance we are extracting a measure of satisfaction from effective retaliation. We are utilising the foreigner to assist in the restoration of an industry which he undermined some years ago.

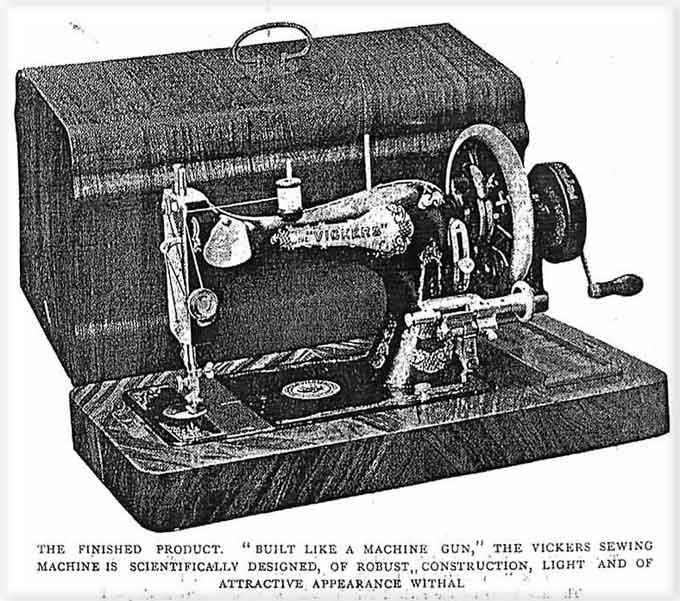

"Built Like a Machine Gun"

As a matter of fact, there is no reason to conceal the circumstance that, from the hard-headed commercial point of view, the Hackney Wick factory cannot by any stretch of the imagination be construed into a businesslike enterprise. Certainly it would have been a useless weapon with which to have countered foreign competition had the latter been permited. Cost of production has soared to a height which could never have been tolerated for a moment in an orthodox factory conducted under normal conditions; it is the financial strength of the Vickers Company alone which has enabled it to be utilised as a means to carry on through a troublous time.

But the money has been fruitfully expended, because it has enabled many valuable lessons to be mastered and has allowed many tedious and expensive experiments to be conducted along more leisurely lines than would be possible under ordinary conditions. Whe the product is transferred from this centre to the well-organised, scientifically equipped and commercially conducted factory it will be possible to essay upon big-scale manuafcture without any preliminary exasperating delay, such as is generally incidental to the embracing of a new range of activity with an unfamiliar product.

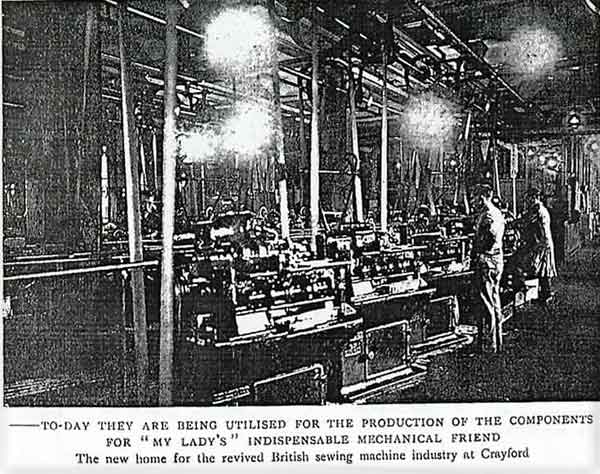

This transference is to be carried out at the first favourable moment. The factories originally designed for this line at Crayford, together with every necessary machine and tool, as well as the labour expert in their manipulation. To the last-named it is immaterial whether the work in hand constitutes a component part of a Vickers gun or a Vickers sewing machine. The one can be made quite as easily, as expeditiously, and cheaply as the other. The probability is that the output will be increased. By adhering as closely to fine measurements in the fabrication of the sewing machine parts as is essential to produce the death-dealing weapon, the subsequent process of assembly can be facilitated and accelerated.

But the labour has become so skilled in working to the two-thousandth part or less of the inch, and that without demanding any more time for the fulfilment of the job, as to present the liklihood of "built like a machine gun" becoming the slogan of the revived British sewing machine industry and indicative of the exellence of its product. Indeed, it will be one of the strongest talking points, one which will sink deeply into the mind of the prospective buyer as representing the highest quality of work humanly possible.

Talking Points of the New Machines

And

what of the sewing macine itself? This is the crucial question, and one which

makes vital appeal to the seamstress, the factories in which textiles are

worked up for commerce, and to the autocrat of the home. Indeed, it is to

My Lady to which the strongest appeal must be made, inasmuch as she is representative

of the largest section of the potential purchasing public. She has to be convinced.

Place in her hands a machine offering the minimum of anxiety, free from liability

to mishap under the most exacting conditions, which will stand up to its work

through thick and thin, is not in constant need of repair or overhaul, and

you have not only won a contented customer, but an admirer of unswerving allegiance

who will never allow an opportunity to escape to impress the unsurpassable

qualities of her mechanical sewing maid upon her friends.

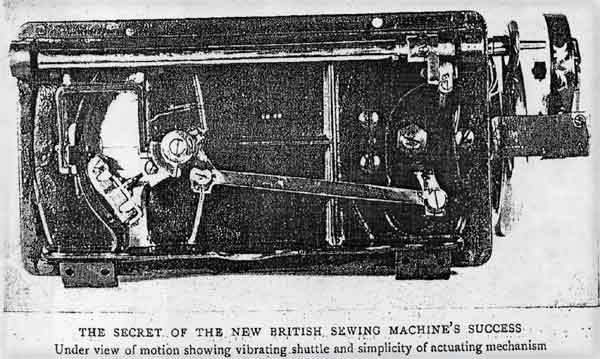

The essential virtues are incorporated in the latest British sewing machines of which I write. Every feature has been made subservient to simplicity for the simple reason that simplicity spells freedom from breakdown and high efficiency. The most satisfactory sewing machine is that having the very simplest mechanism and possessing few working parts. Competition has accentuated this factor, and so, to secure an unassailable foundation, the company reverted to fundamental principles. In this way they have secured the simplest form of approved motion.

Materials then occasioned close observation. In this connection the unique experience of the company in matters pertaining to metallurgy, which is of a far-reaching character, resulting in the production of materials possessing the maximum of strength with the minimum of weight, has proved of inestimable value. These acheivements have enabled the machine to be transformed from a cumbersome and weighty article into one of pronounced lightness, yet absolutely rigid and capable of carrying out both light and heavy work.

Finally there comes the question of fabrication of the components, these being made with the precision of the integral parts of a quick-firing gun, giving extreme accuracy in fitting and perfect adjustment, together with perfect balancing. With these factors speed and silence in running is assured. This machine will work faster without any vexatious breakage of the cotton or disaster to the needle than is likely to be demanded by the average user, but nevertheless is free from any tendency to run away, being at all times under complete control.

These are the first and outstanding points to make appeal to My Lady. Their complete expression will not fail to arouse her severely critical eye and touch. She will then observe that, although this represents an entirely new machine, it is one completely free from what may be described as untried features. In reality it is the oldest and most trusty friend in a new and modern guise. The vibrating shuttle follows the simplest lines -- those which have been proved as completely reliable through thirty years of accumulated experience and use. Novelty, at all events so far as the basic principles are concerned, is conspicuous by its absence, so that no apprehensions concerning working efficiency need be entertained.

Refinements which Count

Now we come to refinements -- the elimination of little worries or the perfection of details which transform the manipulation of a sewing machine from drudgery to pleasure. In this machine all the latest improvements which have established their utilility and which contribute to superior and cleaner work have been incorporated. There is the reversible feed, whereby the operator is enabled to sew backwards or forwards without removing the work. The machinist may commence the work at any convenient point. By the movement of a small lever the machine, when started, will sew backwards to the very edge of the material. Reversal of the lever causes sewing to proceed forward in the usual manner. The end of the thread can then be cut off with the assurance that the seam will not come undone.

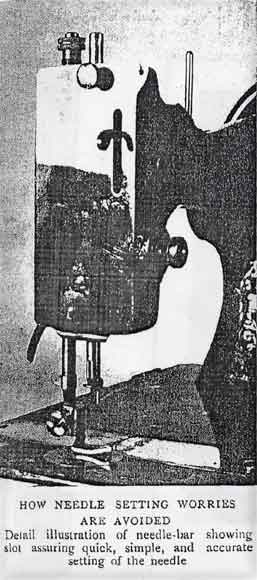

If there is one feature more than any other of the sewing machine likely to prove exasperating, it is the setting of the needle. Certainly it is a detail which has occupied prolonged study. To avoid rousing the machinist's ire, it should be capable of being set with the utmost facility and celerity even in the most adverse circumstances, such as indifferent illumination. The new machine is so designed as to render the needle self-setting. It is held in a slot in the needle-bar and in such a manner as to prevent it being placed too high or too low. It can only occupy one position -- that essential to work the machine.

The machine is symmetrically designed, a conspicuous feature readily appealing to the user being the ample space under the arm which enables large work to be fulfilled with the facility with which small work can be carried out. Of recent years considerable ingenuity has been displayed in adapting the sewing machine to a wide variety of work merely by the aid of suitable attachments. The new aspirant for appreciation is no exception to this rule, being provided with a set of sixteen attachments, instructions concerning the use of each of which are extended.

While the mechanism is the factor which counts, the user, particularly My Lady of the house, appreciates an attractive finish and compactness of the whole, more especially if it be a treadle model. This machine is well japanned and tastefully decorated, while it may be readily identified from the name of the manufacturers plainly imprinted on the arm. It is mounted upon an ample wooden base of solid wood finished in a substantial walnut veneer. In the case of the hand and treadle model, which is now being introduced to the market, a well is provided, into which the base of the hand machine fits, and in such a way as to bring the bed-plate of the machine flush with the surface of the table.

Catering for the Demand

The treadle attachment and table are of light though ample construction, one departure from the usual practice being the provision of a metal instead of a wooden pitman. Weight has been judiciously pared down without sacrificing the rigidity of the stand, thereby facilitating its movement about the room, while special attention has been devoted to rendering it as compact as conditions will permit, so that it does not occupy too much space. It is intended to modify the treadle type of machine to meet varying desires, as, for instance, the provision of a drop head where the machine may be rolled over to become nested in a well when not in use, thereby allowing the stand to be converted into a small occasional or side table.

Incidentally, in the bold decision to restore Britain's lost sewing machine trade, Vickers Limited have introduced a new industry to these islands. This is the production of bent woodwork, which five years ago was virtually an Austrian monopoly. A sewing machine without a bentwood cover of pleasing lines would be akin to jam without sugar. Foreign supplies being cut off, the company was thrown back upon its own resources, which, however, in this as in other directions during the strenuous four years which have passed, proved equal to the occasion. The experimental staff and designers set to work and have succeeded in inventing new machinery capabe of carrying out this working in wood in a manner quite equal to the best which ever came from Austria, and which finds its first commercial expression in the production of the cover for the sewing machine.

While the Vickers organisation has concentrated its energies upon the production of a fully trusty typr of sewing machine of superior manufacture, it must not be thought for a moment that the company proposes to rest content with this model as a solitary expression of its capabilities in this field. The inventive side of the firm, recognising the undeveloped potentialities of the trade, have concentrated their cumulative powers of thought upon the perfection of a rotary shuttle sewing machine for which they hold patented improvements, and this is only a forerunner of other striking develpments which are under way.

Producing and Attractively-priced Article

Standardisation hs tended to stultify inventiveness in this realm. Yet it is one offering illimitable scope, especially to a firm which, new to the craft, is not bound by obsolete traditions and has nothing to forget in order to forge ahead. The rotary shuttle machine is ready for production the moment the works are ready to receive it. As a certain period of time must necessarily elapse before the Crayford factories will be able to get into their stride, the rotary model will not make its appearance until a later date.

When manufacture under scientific factory conditions is attached in grim earnest, effort will be concentrated rather upon speeding up produciton to the maximum. I happen to know what is the aim of the company in this connection, but it would not be fair to communicate it at the present moment. It must suffice to say that the figure is impressive. It should not only suffice to keep the German machine off the Imperial market, but it should render the Teuton reconquest of neutral markets a matter of extreme difficulty.

The cost of production in the German factories under pre-war conditions is fully known. Our ability to eclipse them under contemporary conditions cannot be doubted for a moment. The current prices for the Vickers sewing machine -- £4 16s 0d for the hand and £7 13s 6d for the hand and treadle models respectively -- may seem high in comparison with what the German rivals commanded five years ago. But it must be remembered that raw materials, wages, and other charges stand at higher levels today. Free recourse to standardisation and big-scale production by means of the latest time, labour, and money saving tools may possibly tend towards a modification of prices at a later date.

The circumstances that labour promises to be adequate, the the integral parts of the sewing machine can be turned out freely by the class of labour which achieved such distinct success in the production of munitions, and that the task imposes the minimum of demand upon the highly-skilled section of the labour market, is a happy augury for the future of the British sewing machine industry. We should certainly be able to regain the prestige which we have lost in this field and be in the position to satisfy that huge market which prefers to pay cash for what it requires so long as the price is attractive.

Seeing that it is the factories, machines, labour, and much of the selfsame materials which for four years have been utlilised to turn out an imposing stream of quick-firing death-dealing weapons, which are now to be diverted to the new range of human endeavour and upon an equally striking scale, onw may truthfully describe the new manifestation of activity as being one of "turning Vickers guns into sewing machines".

*********************************************************

This page may not be reproduced or distributed in part or in whole without the prior written permission of the copyright owner